Horus Energy company offers stations unique experience in the field of diagnostics and monitoring the technical condition of existing units, its repair, maintenance and update.

Existing equipment servicing

- Overhaul of main and auxiliary equipment aimed at enhancing its design performance, adding or modifying certain functions (condensation units’ switchover to heating operation mode, extraction switchover between heating and generating modes), and even complete replacement with new equipment.

- Main and auxiliary equipment modernization involving the replacement of some main assemblies or components at our factory or at the power plant.

- Modernization and replacement of equipment made by other manufacturers.

- Warranty service.

- Technical support during scheduled preventive maintenance.

- Quick servicing.

- Technical support, including by supervision staff, during unscheduled repairs, participation in damage-cause investigations.

- Provision of spare parts and special materials.

- Evaluation of the optimal renewal period following diagnostics and special calculations during service life renewal.

- Designer’s supervision.

Services for equipment package deliveries:

- Technical supervision during power-generating equipment installation and commissioning and putting equipment into operation.

- Technical supervision during equipment adjustment (for some equipment types).

- Warranty services, participation in scheduled repairs, development of repair procedures.

- Solving problems during operation, assistance in mastering the operation of pilot and new equipment.

- Adjustment of pilot-equipment components after installation.

- Customers’ personnel training and customer-contractors’ personnel training, consulting services.

- Post-warranty service.

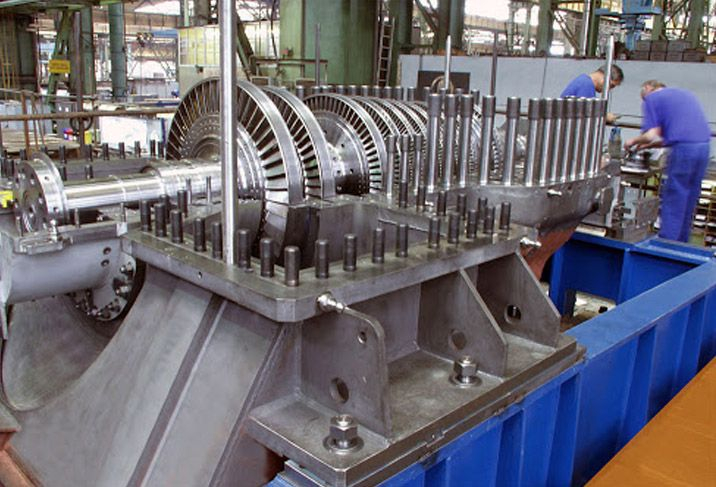

Servicing of steam turbines for TPP:

- Full or partial modernization of high-, intermediate- and low-pressure cylinders with or without steam-flow rate buildup in order to increase power and efficiency by 2 to 12% and reduce specific fuel consumption by 3 to 10% (depending on the scope of the overhaul, initial equipment condition and local conditions).

- Process extraction steam turbine modernization in order to increase their throughput due to reduced steam consumption for production purposes.

- Turbine overhaul in order to adapt the main and auxiliary equipment of the unit to the combined cycle.

- Provision of additional extractions from the high-, intermediate- or low-pressure cylinders of 60 to 300 MW turbines to meet customers’ requirements in process- and heating-steam extractions.

- Installation of 25 to 70 MW supplementary turbines utilizing unused process bleed steam.

- Provision of controlled heating-steam extractions for 200 to 1200 MW condensing turbines to achieve a thermal power of 100 to 500 GCal/h.

- Modernization of valves, steam distribution and control systems.

- Modernization of control, vibration monitoring and diagnostics systems.

- Condenser replacement and auxiliary equipment enhancement.

Hydraulic turbine servicing:

- Replacing runners with more efficient ones.

- Replacing the runner blades of Kaplan turbines.

- Replacing hydraulic turbine guide vanes.

- Replacing unit bearings and shaft seals.

- Replacing electromechanical governors with electronic governors.

- Replacing flowpath component materials with cavitation-resistant ones.

- Installation of polymer guide vanes and bearings not requiring lubrication in runner friction components.

Servicing of the steam turbines of combined-cycle units

- Long-term (3-15 year) servicing of the equipment of combined-cycle units, including (at the customer's request) spare part supply, technical support, engineering, training and operation support services, which are also available via a system for the online remote monitoring of equipment operation.

- Modernization of gas turbines and combined-cycle units CCGT aimed at increasing their power capacity, efficiency and reliability.

- Steam turbine repairs during scheduled and minor repairs, medium and major on-condition overhauls and emergency repairs, including spare part supply and associated works.

- Provision of supervising engineers during repairs; supply of spare parts and performance of related work.

Turbogenerator and hydroelectric generator servicing:

50 – 165 MW turbogenerators:

- Replacement of indirectly-cooled generators with air-cooled turbogenerators allowing for an increase in generator capacity.

- Rotor modernization involving retaining-ring replacement with body-mounted retaining rings made of corrosion-resistant steel.

- Complete and partial replacement of stator windings.

- Modernization of operating performance control and monitoring systems.

165 – 320 MW turbogenerators:

Modernization of ТВВ-series hydrogen-water-cooled turbogenerators involving the rewinding of stator windings and a transition to ТВФ-series turbogenerators with indirect hydrogen-cooling of the stator winding and the elimination of a stator winding water-cooling system:

- TVV-165-2 to TVF-165-2;

- TVV-200-2 to TVF-200-2;

- TVV-320-2 to TVF-320-2;

200 – 300 MW ТГВ turbogenerators:

- Replacement of ТГВ-200 and ТГВ-200M generators with air-cooled or hydrogen-water-cooled generators;

- Replacement of ТГВ-300 generators with hydrogen-water-cooled generators;

- Modernization of operating performance control and monitoring systems.

200 – 500 MW turbogenerators:

- Stator modernization including the replacement of lamination end zones and stator winding replacement;

- Rotor modernization involving retaining-ring replacement with new design rings made of corrosion-resistant steel;

- Stator replacement with new, modernized design stators;

- Increase in generator capacity to cover turbine modernization needs;

- Modernization of stator winding heat-monitoring equipment;

- Modernization of operating performance control and monitoring systems.

800 – 1000 MW ТВВ and ТЗВ turbogenerators:

- Stator modernization including the replacement of lamination end zones and stator winding replacement;

- Complete or partial replacement of four-pole generators’ stator windings;

- Old stator replacement with new, modernized design stators;

- Modernization of stator winding heat-monitoring equipment;

- Modernization of operating performance control-and-monitoring systems.

Hydroelectric generators:

- Stator replacement;

- Replacement of lamination cores and stator windings;

- Rotor pole modernization;

- Modernization of hydrogenerator thrust bearings and other bearings using composite materials;

- Modernization of operating performance control and monitoring systems.

Excitation system, turbogenerator and hydroelectric-generator servicing

- Inspection and modernization of all excitation system types;

- Repair, commissioning and testing of digital excitation systems at power plants;

- Replacement of the rotary converter excitation systems of generators with independent excitation thyristor systems and static systems with microprocessor monitoring and control.